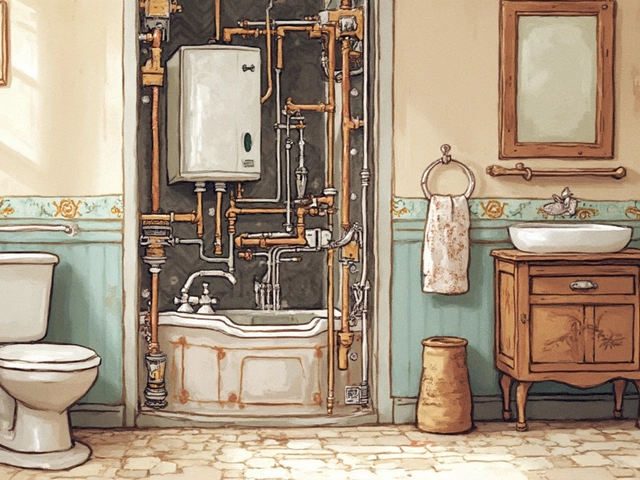

When working with boiler diagnosis, the process of identifying faults in a heating system before they lead to costly breakdowns. Also known as boiler troubleshooting, it forms the first step toward safe, efficient heating. Effective boiler diagnosis often leads straight into boiler repair, where technicians replace or fix the faulty component, and sets the stage for regular boiler service that keeps the system humming.

Most homeowners notice a few tell‑tale signs: strange noises, uneven heat, or a sudden rise in energy bills. Those symptoms point to deeper issues like a failing heat exchanger or a bad pump. Detecting them requires basic tools—a multimeter, pressure gauge, and sometimes a thermal camera. In the UK, a faulty boiler can also become a safety hazard, especially if carbon monoxide leaks; that’s why boiler safety checks are non‑negotiable. If you also run a heat pump alongside your boiler, the two systems share similar diagnostic steps, but the refrigerant loop adds its own set of checks.

First, collect data: note error codes on the control panel, listen for ticking or whistling sounds, and feel for uneven water pressure. Next, verify the power supply and gas flow—these are the arteries that keep the boiler alive. Then, test the ignition sequence; a weak spark often means the igniter needs replacing. Finally, inspect the combustion chamber for soot buildup; excess soot can trigger safety cut‑offs. These actions illustrate the semantic triples: boiler diagnosis encompasses fault code reading, accurate diagnosis requires proper testing tools, and regular boiler service influences the need for major repairs. Each step builds on the last, moving you from simple symptom spotting to a full‑scale assessment.

Understanding why a boiler behaves oddly also helps you decide whether to DIY a quick fix or call a professional. Small tasks—like bleeding radiators or resetting the low‑pressure switch—can be done safely with a few minutes of effort. However, anything involving gas lines, high‑temperature components, or carbon‑monoxide detection should be left to a Gas Safe registered engineer. This distinction saves money and prevents dangerous situations. Moreover, a thorough diagnosis gives you a clear picture of upcoming maintenance costs, allowing you to budget for part replacements or a full system upgrade.

When you’ve run through the checklist, you’ll see a clear picture of your boiler’s health. Below, you’ll find a curated set of articles covering everything from resetting water heaters to understanding heat‑pump efficiency, each written to help you act confidently. Whether you’re hunting for a quick DIY fix or planning a professional service, these resources give you the knowledge to keep your home warm and safe.

Step‑by‑step guide to diagnose common boiler problems, covering pressure, thermostat, fault codes, leaks, and when to call a professional.

Exploring the value of repairing a freezer involves assessing various factors, such as the cost of repairs, the appliance's age, and the efficiency improvements of newer models. Understanding common freezer problems can help homeowners decide whether a repair is worthwhile. The decision should account for both economic and environmental perspectives, guiding when to repair or replace.

Stuck with a broken boiler and a cold house? This guide shares quick, practical steps to keep your home warm without a working boiler. Learn about safe heating alternatives, ways to trap heat, and smart tricks for getting through chilly nights. Find out what to avoid, when to call a professional, and how to prep for future breakdowns. Perfect for homeowners who want to stay safe and comfortable during a boiler emergency.

A failing water heater element can leave you in the chilly lurch just when you need a warm shower. Learn how to diagnose the problem with simple, straightforward steps. This guide covers common symptoms, testing methods, and practical tips for handling a faulty element. We'll explain what's involved and offer insights for DIY repair or knowing when to call a professional.

Curious about how your home appliances actually work? Get a full breakdown of what happens inside, troubleshooting tips, and smart ways to keep everything running smoothly.

When your water heater only puts out cold water, it’s more than just annoying—it can point to real problems inside the unit. This article breaks down the most common reasons behind a water heater that refuses to warm up, from tripped breakers to busted heating elements. You’ll find tips on quick checks you can do at home before calling a pro, plus some unexpected facts about how water heaters really work. Knowing what’s wrong can save you from a frigid morning shower and a giant repair bill. Get ready to tackle that cold water problem with practical advice you can use right away.