Boiler Problem Diagnosis Tool

Select the symptoms you're experiencing to get targeted diagnostic guidance.

Common Boiler Symptoms

When your home’s heat sputters or the hot water disappears, the first question is usually “what’s wrong with the boiler?”. A clear boiler diagnosis saves time, avoids costly calls, and keeps you safe. Below is a practical walk‑through that lets you pinpoint the issue before you ring a technician.

Understanding Common Boiler Symptoms

Boilers can manifest a handful of tell‑tale signs. Recognising them early helps you match the symptom to the right component.

- Radiators are cold on one side but warm on the other.

- Pressure gauge reads below 1 bar or spikes above 2.5 bars.

- Thermostat displays the set temperature but the room stays chilly.

- Unusual banging, whistling, or a burning smell.

- Flashing error codes on the control panel.

Safety First: When to Call a Professional

If you smell gas, see flames outside the boiler casing, or notice water pooling around the unit, evacuate the house and call Gas Safe‑registered emergency services. These situations are beyond DIY and require an expert.

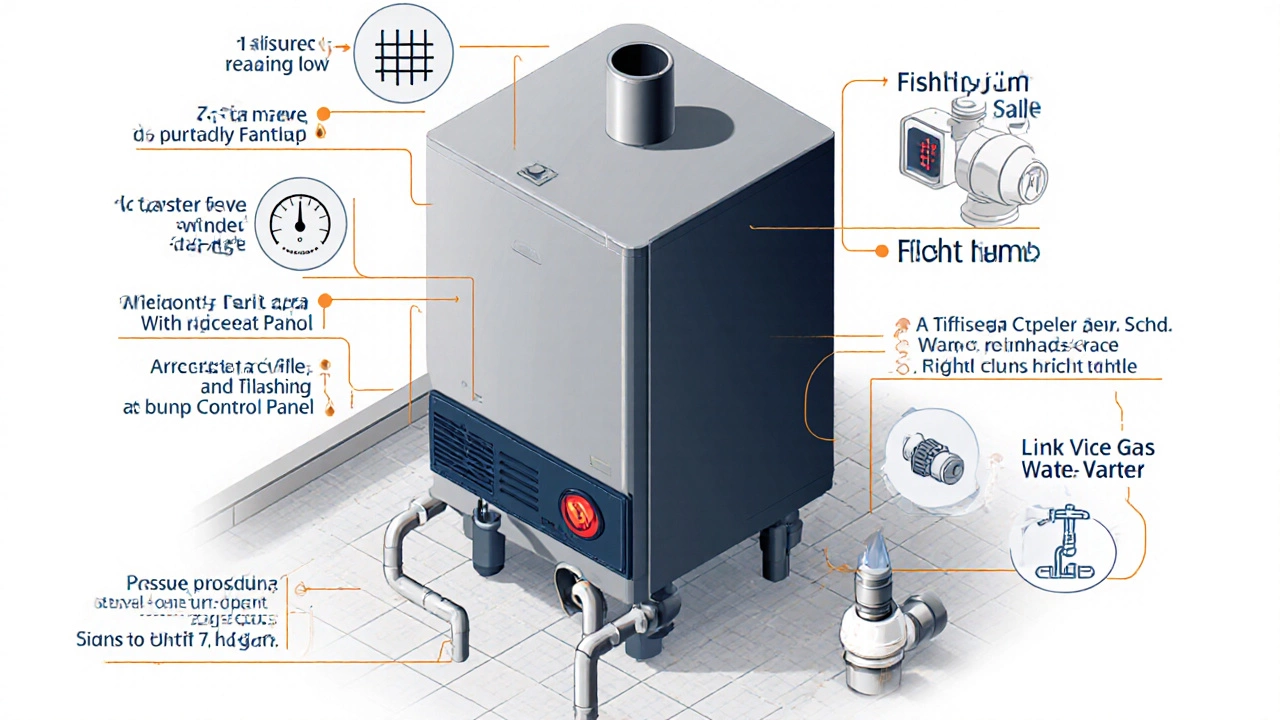

Step 1: Check the Pressure gauge is the small dial that shows the boiler’s water pressure

Locate the gauge on the front panel. Normal operating pressure is usually between 1.0 and 1.5 bar when the system is cold. If it’s below 1 bar, the boiler may not fire; above 2.5 bar could mean over‑pressurisation and a possible valve fault. To adjust low pressure, follow the manufacturer’s refill instructions - usually a half‑turn of the filling loop until the gauge reaches the recommended range.

Step 2: Inspect the Thermostat is the wall‑mounted controller that tells the boiler when to heat

Make sure the thermostat is set to a temperature higher than the current room temperature. If it’s battery‑powered, replace the batteries. Confirm that the thermostat’s “on” indicator lights up; a dead unit may need replacement.

Step 3: Look for Fault codes are numeric or alphanumeric messages displayed on the boiler’s control panel

Modern boilers flash a code like “E07” or “F32”. Grab the user manual (or search the model online) to decode it. Typical codes include:

- E01 - ignition failure.

- E07 - low water pressure.

- E11 - flame detection issue.

Once you know the meaning, you can target the right component - often the gas valve or flame sensor.

Step 4: Test the Circulator pump is the motor that moves hot water through the radiators

Listen for a faint humming when the boiler is on. If you hear silence or a grinding noise, the pump may be stuck or failing. Turn off the power, then manually spin the pump’s shaft (most models have a small access slot). Free movement means the bearings are okay; resistance suggests a replacement is needed.

Step 5: Examine the Gas valve is the component that controls gas flow to the burner

When the boiler fails to ignite, the gas valve could be closed or faulty. With the boiler off, locate the valve (usually a rectangular metal box). A gentle tap with a screwdriver handle sometimes free‑wheels a stuck valve. If the issue persists, replace the valve - but only if you’re qualified, as handling gas components is regulated.

Step 6: Scan for Leaks are any unwanted water or condensation escaping from the boiler system

Check around the pipe joints, the boiler base, and the pressure relief valve for drips. Small condensation is normal, but steady streams indicate a seal failure. Use a dry cloth to trace the source; a persistent wet spot near the expansion tank often points to a pressure‑relief valve issue.

Quick Checklist

- Read the pressure gauge - aim for 1-1.5 bar.

- Verify thermostat settings and battery.

- Note any flashing fault codes and decode them.

- Listen for the circulator pump’s hum.

- Inspect the gas valve for obvious blockage.

- Search for leaks around seals and valves.

- Record any unusual noises or smells.

| Symptom | Likely Cause | Suggested Action |

|---|---|---|

| No heat, boiler silent | Low pressure or gas valve closed | Check pressure gauge; reset gas valve if safe |

| Radiators warm at top, cold at bottom | Air trapped in system | Bleed radiators using a key |

| Flashing E07 code | Pressure below 1 bar | Re‑pressurise via filling loop |

| Whistling noise | Air in pipework or pump cavitation | Purge air, check pump condition |

| Water pooling near boiler | Leaking seal or pressure‑relief valve | Replace faulty seal; call professional if unsure |

When the DIY Path Ends

If you’ve run through the checklist and the boiler still won’t fire, it’s time to schedule a qualified service. Keep a record of the symptoms, pressure readings, and fault codes - this information speeds up the technician’s diagnosis.

Frequently Asked Questions

Why does my boiler lose pressure after it shuts off?

When the system cools, water contracts and the pressure drops. A small leak in the expansion vessel or a faulty pressure‑relief valve can exaggerate the loss. Checking for drops over a few hours helps you decide if a repair is needed.

Can I reset a boiler myself?

Most modern boilers have a reset button on the control panel. Press it for a few seconds after the unit has cooled down. If the fault recurs, note the error code and seek professional help.

What does a flashing orange light mean?

An orange flash usually signals a non‑critical fault, such as low pressure or an overheating sensor. Consult the manual to translate the pattern; often a simple pressure adjustment or air bleed resolves it.

Is it safe to bleed radiators myself?

Yes, as long as the system is cool and you have a radiator key. Open the bleed valve slightly, catch the escaping water in a bowl, and close it once air stops coming out.

How often should I have a boiler serviced?

An annual service by a Gas Safe engineer keeps the unit efficient and prolongs its lifespan. Schedule it before the heating season begins.