If you're about to spend thousands on a heat pump-or you're staring at an older unit wondering if it’s on borrowed time-the number you want is the years it’ll actually last. Here’s the straight answer for the UK, plus what moves that number up or down, and a simple way to decide whether to fix or replace.

- TL;DR: Air source heat pumps in the UK typically last 15-20 years; ground source units 20-25 years, with ground loops often 50+ years.

- Installation quality, sizing, and water/air quality matter more than the badge on the case.

- Do small, regular maintenance: keep airflow clear, clean strainers/filters, check glycol/inhibitor, and set low flow temps.

- Rule of thumb: if a major repair is >40% of replacement cost and the unit is >10 years old, consider replacing.

- Expect better efficiency from newer models; the energy savings can offset part of the upgrade.

How long do heat pumps last in the UK (and what actually counts as “end of life”)?

In UK homes, the average lifespan depends on the type, the install, and how you run it day to day. The headline: air source heat pumps (ASHPs) usually run 15-20 years; ground source heat pumps (GSHPs) often reach 20-25 years, and their buried plastic ground loops can push past 50 years when installed right. That’s what you’ll hear echoed by Energy Saving Trust, UK MCS installers, and long-term ASHRAE equipment life studies.

Why the range? Heat pumps don’t die from birthdays; they die from stress. Short cycling beats up compressors. Poor water chemistry eats pumps and plate heat exchangers. Blocked airflow and cramped installs lead to high pressures and early failures. Get those right, and the calendar stretches.

What counts as end of life? Not one part failing. Most components are replaceable. The end usually comes when the compressor or inverter fails after warranty, the refrigerant circuit develops a leak that’s costly to trace, or the unit needs several expensive parts in quick succession. At that point, you compare the repair bill with the cost and efficiency of a modern replacement.

Here’s a practical snapshot of real-world lifespans, component stresses, and what you can expect in the UK climate (mild, damp winters with a few cold snaps):

| Type / Part | Typical UK service life | What shortens life | Notes (UK context) |

|---|---|---|---|

| Air Source Heat Pump (whole unit) | 15-20 years | Short cycling, poor siting/clearances, coastal corrosion, blocked coils | Mild UK winters help; damp air means more defrost cycles in cold snaps |

| Ground Source Heat Pump (indoor unit) | 20-25 years | Bad water/glycol treatment, undersized ground loop, frequent high-temp operation | Quieter life indoors; fewer weather stresses |

| Ground loop (HDPE) | 50+ years | Incorrect antifreeze, contaminated backfill, poor fusion joints | Usually outlasts the house if designed/installed to MCS MIS 3005 |

| Compressor | 12-20 years | Frequent starts, high discharge temps, low refrigerant, dirty coils | Inverter control helps by modulating rather than hard-starting |

| Fan motors (ASHP) | 10-15 years | Debris, bent guards, imbalance, ice damage | Simple swap; not a reason to replace the whole unit |

| Circulating pumps | 8-15 years | Sludge, air ingress, running dry, incorrect speed | Protect with strainers, deaeration, and inhibitor per BS 7593 |

| Plate heat exchangers | 10-20 years | Scaling, corrosion from poor water chemistry | Treat/flush system; check inhibitor annually |

| Controls/inverter boards | 10-15 years | Moisture ingress, voltage spikes | Use surge protection; keep covers/gaskets intact |

| Typical parts warranty | 5-10 years (with accredited install/servicing) | N/A | Check manufacturer UK schemes; some offer 7-10 years if registered |

Industry references worth knowing: Energy Saving Trust has repeatedly stated 15-20 years for ASHPs with good maintenance, and longer for GSHPs. ASHRAE equipment life data pegs heat pumps in that same ballpark, with ground loops designed as a long-lived asset. UK MCS MIS 3005 sets the ground rules for proper design and installation. Manufacturers’ literature and UK installer schemes typically give 5-10-year parts warranties when you register and service on schedule.

Two UK-specific quirks to factor in:

- Defrost in damp cold spells: When it’s 0-5°C and humid, ASHPs defrost more often. That’s normal, but it adds some wear. Keeping coils clean and airflow clear reduces the hit.

- Coastal air: Salt mist corrodes fins and fasteners. If you’re near the Bristol Channel or south coast, ask for coastal-rated coatings and rinse the unit occasionally with fresh water.

Rough usage hours? In a typical well-insulated UK home, expect 1,500-3,000 compressor hours per year. Lower flow temperatures, good weather compensation, and decent insulation keep that toward the lower end.

How to extend lifespan: setup, habits, and a simple maintenance plan

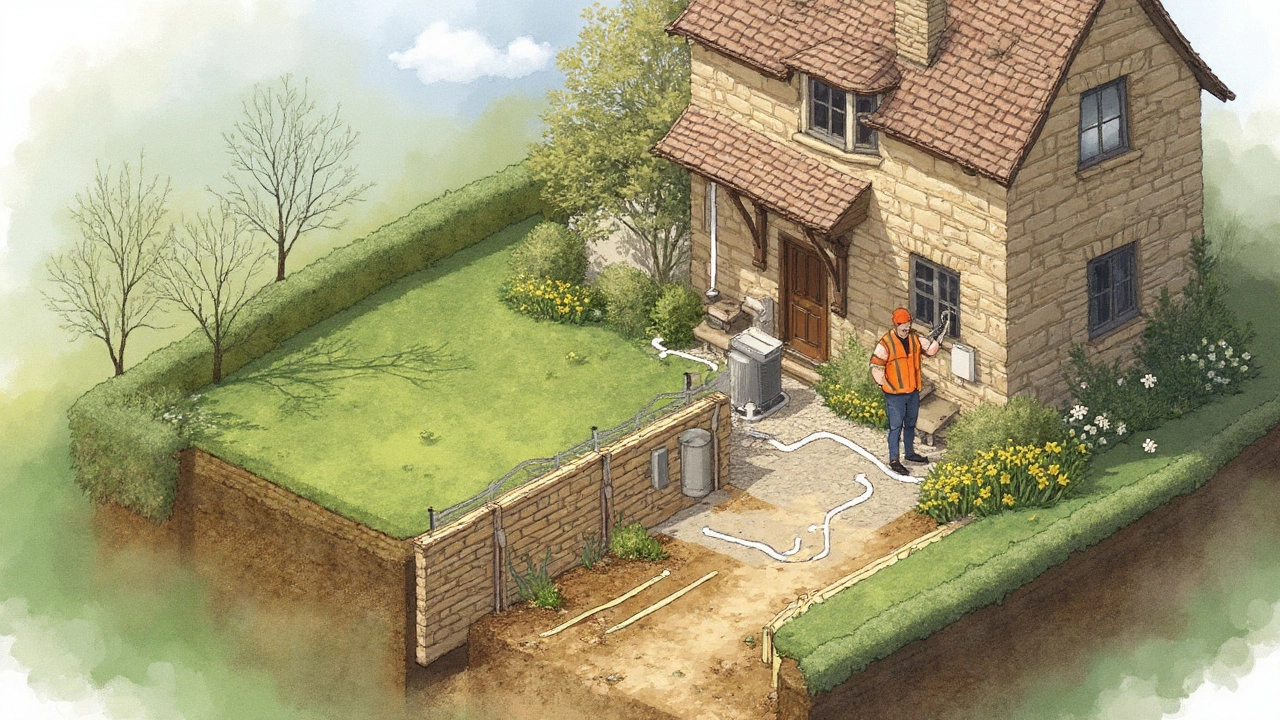

If you lock in the basics-clean air/water paths, steady running, and sensible temperatures-you add years. Here’s a clear plan you can follow without turning into an engineer.

First, the golden rules that make the biggest difference:

- Keep flow temps low. Aim for 30-45°C on radiators sized for low temp, 30-35°C for underfloor most days. Lower temperatures = less compressor stress.

- Let it modulate. Don’t keep switching it off and on. Use weather compensation so the unit trims output rather than hard-starting.

- Protect water quality. Treat to BS 7593, fit a strainer (and ideally a magnetic filter), and test inhibitor annually.

- Give it breathing room. Maintain manufacturer clearances around the outdoor unit and keep vegetation and bins away.

- Size for steady running. Oversized units short cycle; undersized ones run flat-out and defrost more. Good MCS design avoids both.

Maintenance checklist and schedule you can stick on the fridge:

- Every month (heating season):

- Walk-around: remove leaves, rubbish, snow, or anything blocking the outdoor coil or fan guard.

- Check system pressure (if sealed hydronic): top up only if it’s drifted; frequent topping up means a leak-call an engineer.

- Glance at fault history on the controller: repeated LP/HP or defrost warnings are an early sign to investigate.

- Every 3-6 months:

- Clean or replace return air/grille filters (if your system has them) and clean strainers on the hydronic side.

- Rinse the outdoor coil with a gentle hose spray (power washing can fold fins). Do this more often near the coast.

- Check that condensate drains freely in cooling/dehumidify mode (for reversible units).

- Annually (ideally before winter):

- Service by an MCS/F-Gas certified engineer: refrigerant checks, electrical, inverter boards, thermistors, and safety controls.

- Test inhibitor and glycol levels; top up to the manufacturer’s concentration. Replace strainers’ seals if perished.

- Verify weather compensation curve, flow rates, and room-by-room balance. Small tweaks cut cycling and lift SCOP.

- Every 5-7 years:

- Proactive parts: consider replacing worn fans or pump cartridges before they fail in January.

- Full system flush if water tests show sludge or high conductivity; refill with inhibitor.

How you run it day-to-day matters as much as annual servicing. A few habit tweaks add years:

- Don’t yo-yo the thermostat. Set a steady target and let weather compensation do the heavy lifting.

- Use night setback, not off. Dropping a few degrees overnight avoids a big morning spike and hard starts.

- If you need high temps (older rads), consider upgrading key radiators to larger ones so you can drop flow temperature.

- Plan for defrost. In frosty weeks, accept a brief pause while the unit clears ice-don’t force it off and on.

- Keep pets away from the outdoor unit and guard against footballs or bikes bending fins.

Install details that pay you back in lifespan:

- Anti-vibration mounts and flexible connections reduce mechanical stress and noise.

- Right location beats fancy covers. Put the outdoor unit where wind doesn’t blast it, with a clear sky above for radiant defrost. Avoid tight alleyways that trap cold, moist air.

- Correct condensate routing so defrost water doesn’t refreeze under the unit.

- Surge protection for the inverter and tidy cable glands to keep moisture out of electronics.

- Documented commissioning: keep the design flow rates, curves, and serials. Future you (or the next engineer) will thank you.

What about refrigerants and the 2025+ landscape? Newer UK models increasingly use R290 (propane) and R32. You don’t need to replace an older R410A unit just because of regulations, but availability and cost of top-ups can tighten. If your older unit develops a big refrigerant leak late in life, that tips the scales towards replacement.

A quick word on real efficiency and why it matters to lifespan: units that hit a seasonal COP (SCOP) of 3.5-4.5 tend to run cooler and steadier. Older installs stuck at 2.5-3.0 often short cycle, run hotter, and need more defrost. Better control strategy today can lift SCOP without touching the hardware.

Repair or replace? A simple decision rule, UK costs, and the signs of end-of-life

I live in Bristol where winters are kind but damp, and I see the same pattern in neighbours’ systems: the first costly bill lands around year 10-14 (fan motor or control board), and the big decision often arrives when the compressor or refrigerant circuit misbehaves. Here’s the calm way to choose without second-guessing yourself.

Use this quick rule of thumb:

- If the repair is under 20% of replacement cost and the unit is under 10 years old, repair.

- If the repair is 20-40% and the unit is 10-15 years old, compare energy savings and warranty status before deciding.

- If the repair is over 40% or the unit is older than 15 years with multiple issues, replace.

Typical UK cost ranges in 2025 (ballpark, installed):

- ASHP replacement: £7,000-£12,000 for a standard 6-12 kW domestic system (more if you add new radiators or cylinders).

- GSHP indoor unit replacement: £9,000-£14,000 if reusing an existing loop; a new borehole system is often £16,000-£25,000+.

- Major repairs: compressor £1,800-£3,500; inverter/control board £400-£1,200; fan motor £200-£600; circulation pump £200-£450; plate heat exchanger £300-£800.

Energy savings from a modern unit can move the needle. A quick back-of-the-envelope example:

- Your home needs ~10,000 kWh of heat per year.

- Old unit SCOP: 3.0 → uses ~3,333 kWh electricity.

- New unit SCOP: 4.0 → uses ~2,500 kWh electricity.

- Saving: ~833 kWh/year. At 28p/kWh, that’s ~£233/year. If your usage is higher (e.g., 15,000-20,000 kWh heat), the saving scales up.

If you’re in England or Wales, the Boiler Upgrade Scheme (BUS) currently offers grants up to £7,500 for both ASHP and GSHP when replacing fossil heating, which can make replacement far cheaper than a big late-life repair. Scotland has separate Home Energy Scotland support. Always check current terms.

Clear signs your unit is nearing the end:

- Repeated low-refrigerant or high-pressure faults-with no obvious mechanical blockage or fan issue.

- Rising noise from the compressor that isn’t a simple mount or fan problem.

- Frequent tripping breakers or inverter faults even after board replacements.

- Efficiency has dropped and won’t recover after servicing: higher run hours for the same weather and setpoints.

- Multiple parts failing within 12-18 months (fan, sensors, board): the cascade effect.

Issues that look scary but are usually repair jobs, not a death sentence:

- Single fan motor failure after a branch or ice hit.

- Blocked strainer causing flow faults; quick clean and balance.

- Room sensor drift; a simple swap.

- Ice build-up after a cold snap due to a blocked drain; reroute and clear.

Mini-FAQ

- What’s the average heat pump lifespan? In the UK, 15-20 years for ASHPs; 20-25 years for GSHPs. Ground loops can last 50+ years.

- Do defrost cycles wear the unit out? They add some runtime, but they’re normal. Keep coils clean and airflow clear to minimise defrost time.

- Does switching it off in summer help? If you’re not using cooling or hot water via the heat pump, you can turn it off. Don’t power-cycle daily in heating season.

- Are older R410A units a problem? Not by themselves. But large refrigerant repairs can be pricier; that can influence the repair/replace call.

- Will bigger radiators really help? Yes. They allow lower flow temperatures, which boosts efficiency and reduces compressor stress.

Next steps and quick troubleshooting

- If your unit is under 10 years and out of action: check the obvious (airflow, strainers, gauges, fault code). Many winter call-outs are blockages or settings.

- At 10-15 years with a big repair quote: ask for a second opinion that includes a SCOP estimate post-repair vs a new unit. Compare warranties and BUS grant eligibility.

- Over 15 years and unreliable: get two like-for-like quotes and one “optimised” quote (e.g., add two larger rads to drop flow temp). Optimising can pay back faster than you think.

- Coastal or exposed site: ask about coastal coating, stainless fixings, and a wind-sensible location. Schedule a gentle coil rinse quarterly.

- Underfloor heating: keep mixing valves and pumps serviced; low temps are your friend-no need to chase 50°C unless for Legionella cycles on hot water.

Simple decision flow you can apply today:

- Note age, known faults, and last service date. Pull the warranty docs.

- Get a fixed-price diagnosis. Ask for the root cause, not just the symptom part.

- Request two options in writing: repair with expected SCOP and life extension vs replacement with SCOP and warranty.

- Apply the 40% rule and factor any grant. If close, pick the option with fewer unknowns and better comfort.

- Whatever you choose, set weather compensation right and clean the strainers. That alone saves headaches.

Credibility checkpoints the pros use: ASHRAE equipment life tables place heat pumps squarely in the 15-20+ year range. Energy Saving Trust guidance mirrors that for UK installs. MCS MIS 3005 and BS 7593 set the expectations for design and water treatment. Manufacturer schemes in the UK often extend parts coverage to 7-10 years when you register and service on schedule. If your plan lines up with those, you’re on firm ground.

One last nudge from a Bristol terrace with a muddy little back garden: most early heat pump failures I’ve seen weren’t destiny-they were dirty strainers, tight clearances, or flow temps set for a boiler. Tidy those up, and you’re back on track for the full lifespan.